Industrial waste processing machines

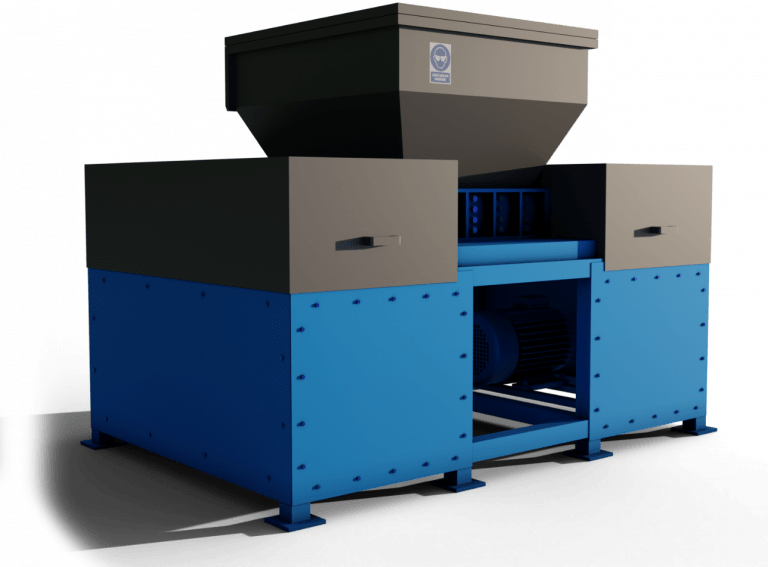

The design of the two-shaft crushers is based on stainless steel, which is responsible for the useful life of the machine and its exceptional durability. The processing of materials through the two-shaft crusher uses a cutting and friction process in the opposite directions. The end product of shredding in this machine is irregular in shape and its size is determined by the width of the cutting discs. The two-shaft crushers can also be equipped with a special hydraulic pusher to process large-volume raw materials by pressing them together.

The operation of a two-shaft crusher is based on the operation of two main shafts, independent of each other, to which the cutting knives are assembled. Each shaft has its own drive. The drive is transmitted from the electric motor by means of a belt transmission to a toothed gear with ratios adapted according to the material to be processed (1:20, 1:30 or 1:40). The final element for the transmission of drives to the main shafts is the WD series toothed gears, which are connected to the shaft by a coupling. The end result of a two-shaft shredder is finished material, which can then be transported or further processed. The two-shaft shredders are perfect for landfill sites, vehicle disposal and waste management facilities, as well as recycling centres.

The two-shaft crusher guarantees low operating costs combined with high productivity. It is able to meet the high production requirements of industrial enterprises. The main advantage of two-shaft shredders is that considerable savings are possible through their use. Furthermore, they facilitate the efficient processing of secondary raw materials. The high torque of these machinery fulfils the high technological requirements for the shredding of materials. The use of two-shaft shredders enables full recovery of the raw material in the processing plant.

The intended use of the machine is shredding:

- aluminium cans,

- metal drums,

- lightweight scrap (maximum thickness 2 mm),

- car and agricultural tyres,

- wood,

- plastics,

- municipal waste,

- cables,

- films,

- electro-waste,

- household products,

- aluminium and steel shavings.

Aztech two-shaft crushers for aggregate and recycling

The two-shaft crushers offered by Aztech are produced using high-quality components. Thanks to the possibility to optimally configure the width of the working knives of the crusher and their compaction, we can obtain material from 20 mm to 80 mm in size. Depending on the crusher model, we use different gear types – WD 400, WD 500 and WD 650. The dedicated drive and appropriately adapted gear ratios make the machinery very powerful. The smallest models in our product range are capable of processing a wide variety of materials, such as tyres, sheet steel, steel drums or cables. The two-shaft crushers offered by the Aztech company are used for even the most difficult tasks with high intensity and low power consumption.