Operating principle of the roller crusher

Two horizontal rollers rotate towards each other. Their surface is adapted to the specific material – in addition to flat, there are also models with serrated and grooved surfaces. The specific solution translates into a better grip (e.g., for larger pieces of raw material). One roller rotates in moving bearings, while the other rotates in stationary bearings and is pressed by a spring. Thanks to this, the machine provides the aforementioned aperture adjustment, while eliminating the risk of damage due to hard parts coming through.

The refined design allows a variety of effects on the material to be shredded – crushing, splitting, abrading and tearing. This makes it possible to process many types of aggregates.

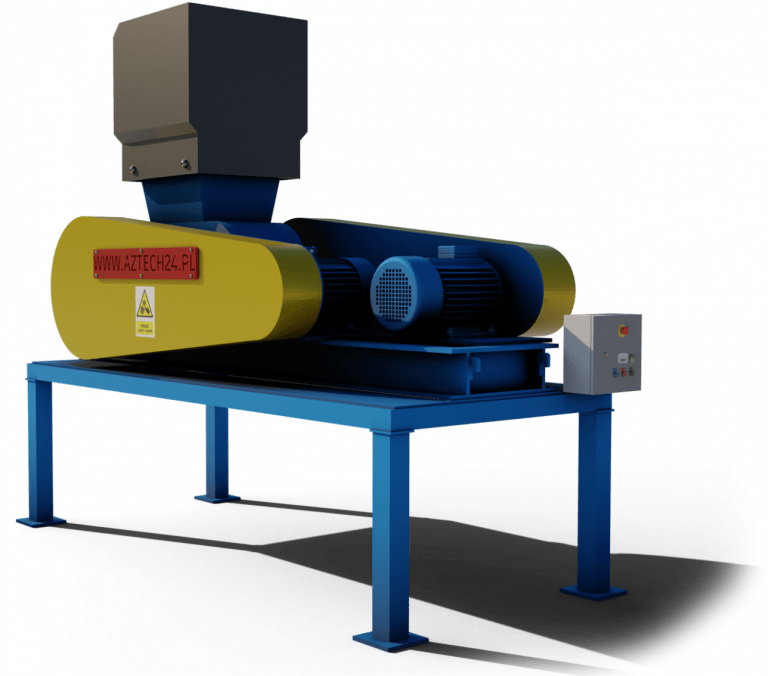

Design of roller crusher

In this connection, it is also worth mentioning that the characteristic design of the roller crusher makes it very suitable for rocks with an increased moisture content. The more water, the weaker the rock, which makes crushing much easier. However, sticking of crusher components is often a concern. In the case of machines in this category, we have to deal with the phenomenon of different roller speeds, so the phenomenon is largely eliminated.

Thanks to rollers made of hardened manganese steel with a wall thickness of 80 mm, the crusher is perfectly suitable not only for the efficient crushing of soft materials such as hard coal, but also very hard materials such as granite, without affecting the structure of the smooth rollers. The technological solutions that we use as basic in each of our machines are as follows: roller bearing lubrication system, double-reinforced bearings.

Main use of the machine - roller crusher for stone?

The roller crusher is used in a wide range of applications, both in the crushing of fossil materials and in the secondary processing. As a result, our crushers are used both for crushing coal in the mines or power plants, scrap material in the foundries, steelworks, as well as concrete and rubble. This makes it possible to recover part of the material, which translates into savings and an environmentally friendly solution.

- granite

- asphalt

- charcoal

- hard coal

- stone

- concrete

- brick

- ceramics

- glass

- chalk

- slag