Innovative solutions in complete crushing lines

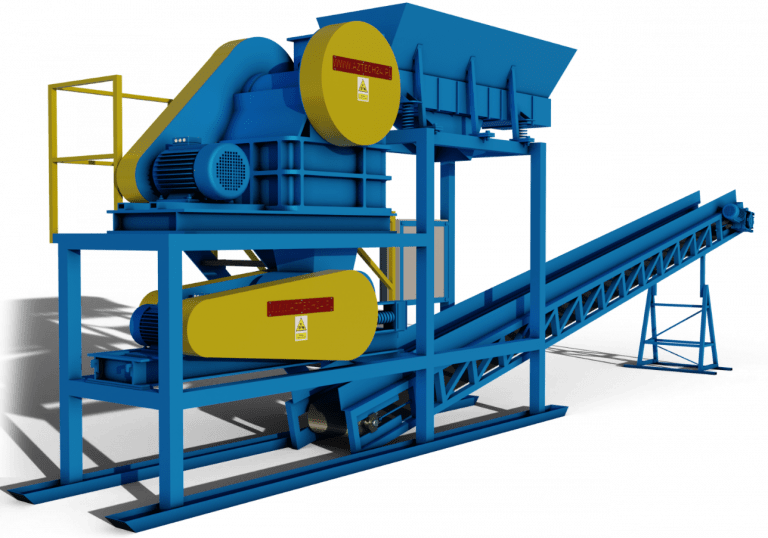

The modern complete crushing line is built on the basis of an innovative design concept of machinery. The foundation of its operation is a technologically advanced crusher. The operation of the crusher requires auxiliary equipment, which is why the crushing line sequence also includes feeding equipment (infeed feeder) and receiving equipment (collection device for crushing product). The construction of the individual components of a complete crushing line determines the degree of crushing of the material. The most technologically advanced crushing lines are machinery for crushing natural aggregates. Mechanical crushing of raw materials offers the possibility of refining them, and screening them facilitates the removal of remaining impurities.

The technological process of crushing makes it possible to determine the stages of crushing, screening and size of the individual components of the final aggregate. Above all, crushing machines are required to have the right capacity and to reduce energy consumption. When selecting a crushing machine, it is worth considering its reliability and energy consumption. The useful life of the machine components and operating costs also remain a key consideration.

The crushing line provides simple operation and guarantees safe working conditions under all conditions. The complete crushing line enables to save money while being an environmentally friendly solution. The modern crushing lines operate extremely efficiently and are able to significantly speed up many industrial processes.

The complete crushing lines are commonly used for mineral aggregates in order to crush them into smaller pieces. The task of innovative crushers is to produce a mixture of any composition that best suits the needs of the enterprise. The complete production lines find their application both in the crushing of natural deposits and in the processing of any material. They are mainly used in the extractive, agricultural, recycling and construction industry. They are excellent for recycling bricks, concrete and other types of stone for use as ballast in the road construction. The material to be crushed is placed in a loading hopper. The crushing hammers crush the raw material and the size of the final product depends on the mesh density of the sieve through which it is screened.

Producer of industrial machinery and process lines

Depending on the type of design, the intended use of the crushing machine changes. In addition to the standard production of stationary equipment, Aztech offers its customers complete lines for crushing, screening and sorting the material to be processed. Each of the crushing lines produced by Aztech is configured based on customer demand and the specifics of the material to be crushed. The complete crushing lines are a great improvement in terms of productivity, as they have automatic systems for feeding, dosing, crushing, screening and stacking of products. We are able to base this type of line on any machine manufactured by our company with a capacity of 4 to 100 t/h.

We customise the capacity and key parameters of the crushing production line according to customer requirements.

Such lines most often include:

- crushers,

- vibrating tables,

- loading hoppers,

- belt conveyors,

- screening machines,

- magnetic separators,