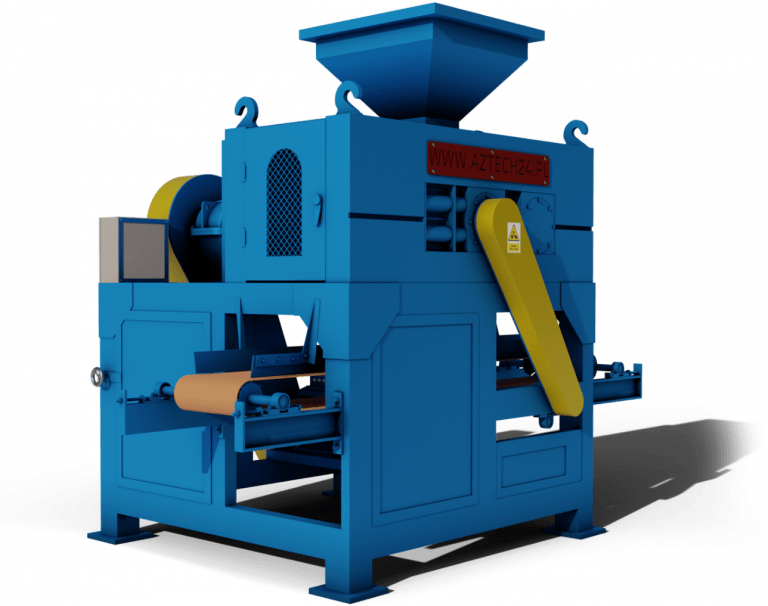

Use of the roller briquetting press

Due to its capabilities, the roller briquetting press is most frequently used for the processing of fine-grained materials characterised by abrasive properties on a mass scale. In the vast majority of cases, these are mining materials such as metal ores, fines, coal, sludge and coal dust.

The class of coal briquetting presses also includes models based on ring technology, but these are far less efficient than roller briquetting presses.

How does a briquetting press operate?

The operating principle of the briquetting press is very similar regardless of the design solutions used. Pressing takes place by mutual pressure of two dies perpendicular to each other.

Thanks to the use of hydraulic roller pressure, materials of different densities can be successfully briquetted. Upon passing through the pressing chamber, the finished product takes the form of a cube, a cylinder, a ball or a rectangle.

All our machinery is equipped with an automatic system of roller release in case an undesirable element/contamination enters the pressing chamber, which could damage the machine.

In our offer you will find machinery in different size variants (power, production capacity). For each machine we are able to adjust the die – (briquette shape), according to the customer’s needs.

Machine dies

- Eco-pea coal briquetted

- Ball briquette

- Pillow briquette (standard)

We recommend all customers to invest in a roller briquetting press. First and foremost, our machines are characterised by an excellent ratio of performance to power. The high efficiency goes side by side with the wear resistance of the tools used. Moreover, the refined and repeatedly tested design allows the machine to operate for long periods under heavy load in even the most demanding conditions.

Customers also appreciate working on the briquetting press because of its simplicity of operation with great possibilities for automating the individual stages. The whole system is extremely reliable and is characterised by low operating and maintenance costs.